Pipe Bursting – A Great Option….Sometimes

Home /

Pipe Bursting – A Great Option….Sometimes

We’ve talked about Pipe Lining and Pull-in-Place. These methods are what they call CIPP, or Cured –

In-Place-Pipe.

Pipe Bursting is a whole other beast. You see both Lining and Pull-In-Place rehabilitate an existing pipe. Pipe bursting on the other hand, well, BURSTS the existing pipe and pulls a new HDPE pipe in behind it.

How does pipe bursting work?

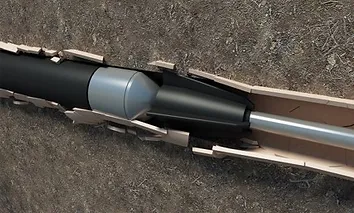

At least two holes are needed, one for the pipe and one for the pulling mechanism. The HDPE pipe is fused to a steel bursting head (we can put fins on it to slice PVC if needed). We can pull approx 150ft at a time. A rod is then run through the pipe to be replaced. A thick steel cable is taped to the rod and pulled back through the pipe.

One end of the pipe is attached to the steel head that the pipe is fused too. The other end is feed through a hydraulic winch. The winch then pulls the steel cable, bursting head, pipe and all through the old pipe destroying it in the process. After it is pulled through you now have a brand new HDPE pipe. You can now connect the existing plumbing to the new pipe. Now lets get into the pros and cons of this process.

(To see the whole process in action click here.)

PROS

There are a few benefits to bursting a pipe as opposed to rehabilitating it. The first might be the most attractive reason.

COST:

The price of the HDPE pipe is relatively inexpensive. The process is also simpler then Lining or Pull-In-Place which helps to keep the cost down.

UPSIZING:

There are times when you have a 3 or 4 inch pipe and you need to upsize to a 6in pipe. This method will allow you to do just that. You can fuse a slightly larger pipe to the bursting head and pull in a larger pipe. Voila… pipe upsized.

CONS

Now there are some serious limitations to this technology that can make us think twice as to using it.

LATERALS:

As we have explained the new pipe being pulled in destroys the old pipe. So what does that mean if you need to replace the mainline under your house or business? Well, each lateral that you have connecting to your mainline is also destroyed (think of your restroom fixtures tying into your mainline). The only way to reconnect it is to dig up the spots with the shattered fittings and reconnect the laterals to the mainline. This means that although there is not a trench, there is significantly more demo then the other methods.

DEPTH:

Your sewer line needs to be about 2ft deep. Most mainlines are deep enough that this shouldn’t matter, however there are always the few that will cause a problem. If the pipe is shallower then that then the displacement caused by the new pipe being pulled in can cause the ground to heave. This can cause at best a heave along the length of the pipe (if the pipe was under dirt) which the dirt would have to be lowered. At worst it can cause cracking of the slab (when pipe is run under the slab). Again this is only if the pipe was placed shallower then about 2ft. This may be the case in an addition of a kitchen or restroom to existing plumbing.

FOOTINGS:

The last con that we will mention is that most pipes that run from inside a home/building to the outside go through the footing of the structure. The fact that the pipe is encased in concrete will cause the winch to spike in pressure and prohibit the bursting process.

Final Thoughts

There is a time and place for everything. So, while pipe bursting can be less expensive we have found that it is best utilized outside the home when there are no connections. Since this method needs two holes, replacing the piping all the way to the city tap could be problematic as well due to the extensive cost of digging in the street for most municipalities.

As I have mentioned before we do offer all of these methods and are committed to using the most cost effective and appropriate method for your situation. Feel free to contact us and I will be happy to answer any question you may have. Have a great day and please stay safe out there.

Your friendly neighborhood Plumber,

Bryan Lopez

Bio Remedies